M-Line - Options and Accessories

ACCESSORIES

IBCs Cleaning System

For IBCs up to 2200 mm (86,6”) high and max diameter/footprint 1600 mm (63”)

For IBCs up to 2200 mm (86,6”) high and max diameter/footprint 1600 mm (63”)- Automatic cleaning head pneumatic lifting system, working range of 2000 mm (78,7”)

- High pressure hydrokinetic head featuring 4 orbital nozzles

- Maximized results for every IBC size and shape, thanks to fine positioning at different heights and 360° coverage of the cleaning head

- Inclusive of AISI 316 S/S lid for bin openings up to DN400

- Support structure lower than 3000 mm (117”), footprint of 405 x 405 mm (16” x 16”)

Drums Cleaning Kit

Suitable for drums with diameter up to 800 mm (31.5”) and height up to 1100 mm (43.3”)

Suitable for drums with diameter up to 800 mm (31.5”) and height up to 1100 mm (43.3”)- Electropolished AISI 316L drum supporting frame; manual adjustable holding system to easily manage different drums sizes

- High pressure hydrokinetic cleaning head with semi-sphere spraying pattern

- Easy to open side protective panels; ergonomic tilting aid tool, allowing drums ergonomic loading and unloading

- Structure, panels and drain tanks made in AISI 304

- Overall dimensions: 1100 x 1200 x 1860h mm (43.3” x 47.2” x 73.2”h)

- Max holding system height: 2500 mm (98.8”)

Drying Mobile Unit

Electrical heat exchanger to warm drying air up to 70°C – 158°F

Electrical heat exchanger to warm drying air up to 70°C – 158°F- Pre-filter (G4) and HEPA (H14) filter equipped with ports for integrity testing and differential pressure monitoring system

- Hot air fan with a flow rate of 700 m3/h (412 cfm) equipped with anemometer for air-speed monitoring

- Siemens or Allen Bradley automation systems FDA CFR 21 part 11 compliant

- Automatic intercept electric valve for back-to-back washing and drying phases

- ASME BPE 4” clamp outlet with multiple length DN100 hoses and S/S 316L passivated lid suitable for bins with max DN400 openings

APPLICATIONS

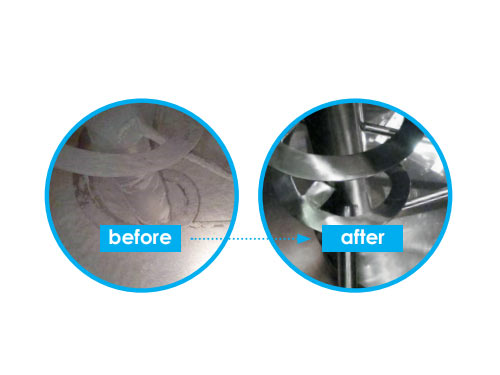

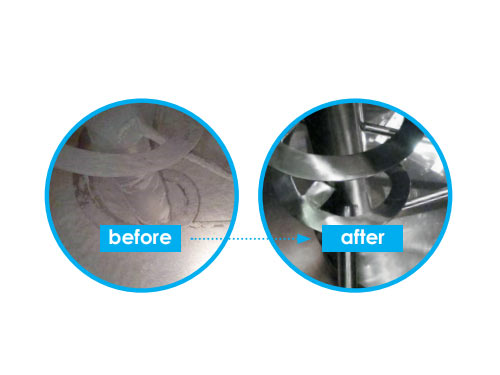

Blender cleaning

Ideal to:

Ideal to:

- Automatically clean a large and tall blender

- Reduce the down-time of the equipment increasing productivity

- Implement a fully validated cleaning process, faster and cost effective

- Increase the safety for the operators

Thanks to M-Line features:

-

Multiple hydrokinetic lances connection for total internal volume coverage

-

70Bar | 1015Psi water pressure for an impressive scraping effect on surfaces

-

7 min total cycle time

-

Low water consumption: only 40l/min | 10gal/min

-

-82% water, -90% time compared to previous manual cleaning process

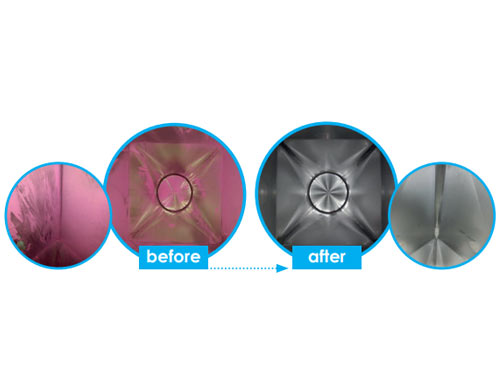

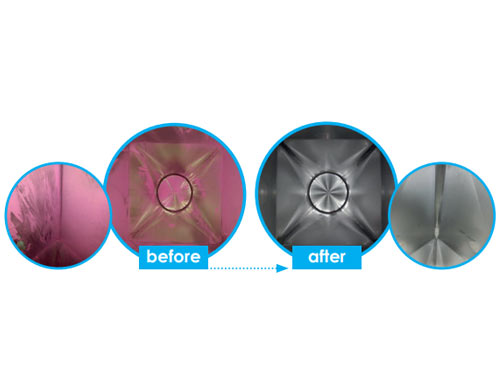

Bin cleaning

Ideal to:

Ideal to:

- Automatically clean IBS of multiple sizes

- Minimise cross-contamination risks through an automated cleaning process

- Shrink storage space thanks to reduced downtime for cleaning

- Reduce water and detergent consumption

Thanks to M-Line features:

- One hydrokinetic lance to fit multiple size containers

- Lid to contain water splashes and allow cleaning of the manhole edge

- Non water-soluble sticky product: Results of cleaning validation

- 2 min washing time with alkaline detergent at 0.1% concentration

- 4 min rinsing with PW

- 240 l / 63 gal water consumption

- In-line conductivity control compliant

- Lab TOC control compliant

- Lower water and detergent consumption: great savings in effluent treatments

ADDITIONAL INFORMATION

Additional features

- Wheel mounted ABS crash-proof covers.

- Quick lock connections for hydrokinetic lances.

- Multiple water quality inlets.

- Detergent dosing stations available.

- On-board electrical cabinet.

- Final rinse water conductivity control.

- Built in compliance with the main regulatory guidelines

For IBCs up to 2200 mm (86,6”) high and max diameter/footprint 1600 mm (63”)

For IBCs up to 2200 mm (86,6”) high and max diameter/footprint 1600 mm (63”) Suitable for drums with diameter up to 800 mm (31.5”) and height up to 1100 mm (43.3”)

Suitable for drums with diameter up to 800 mm (31.5”) and height up to 1100 mm (43.3”) Electrical heat exchanger to warm drying air up to 70°C – 158°F

Electrical heat exchanger to warm drying air up to 70°C – 158°F Ideal to:

Ideal to: Ideal to:

Ideal to: