Contact IWT Pharma direct or your Account Manager for further information.

Enter your password to download the catalogue:

New to IWT? Get your password!

Forgot your password? Request it!

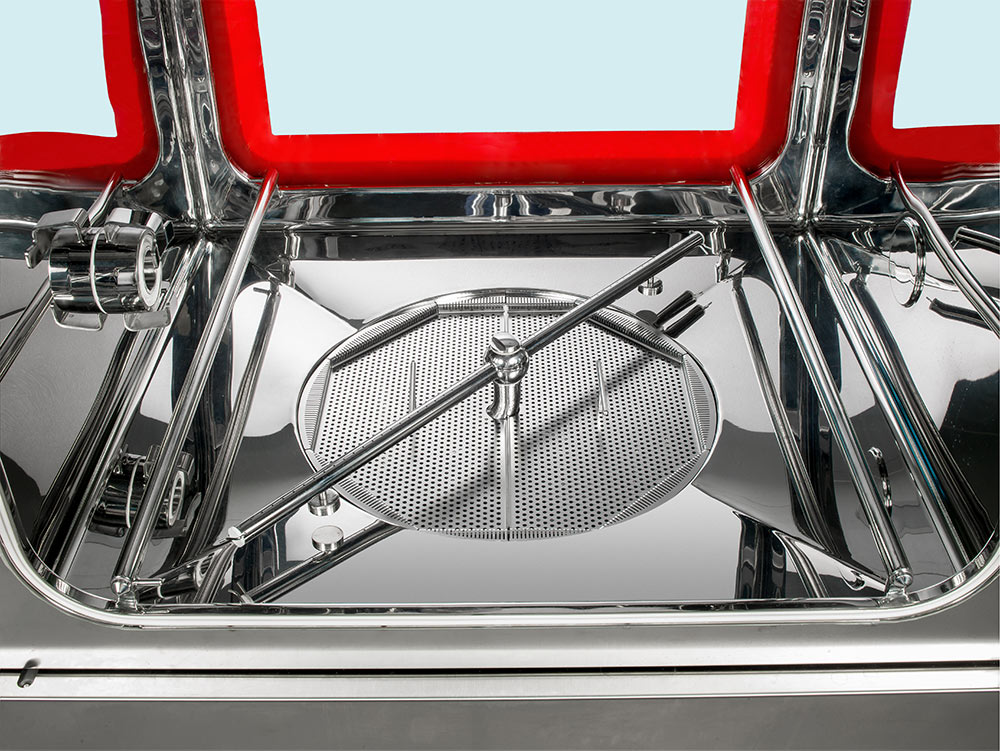

Best-in-class ratio between chamber and total volumes in the smallest footprint for parts cleaning:

|

200 EVO Model |

060 |

100 |

140 |

|

Chamber Nominal Volume [m3 – ft3] |

>0.6 – 21.2 |

>1.00 – 35.3 |

>1.4 – 49.4 |

|

Footprint [m2 – ft2] |

~ 1.2 – 12.9 |

~ 1.8 – 19.4 |

~ 2.5 – 26.9 |

|

Unit height [mm - ft] |

2500 - 8.2 |

||

|

Unit total volume [m3 – ft3] |

3 – 105.8 |

4.5 – 159.1 |

6.3 – 220.6 |

|

Ratio |

20% |

22% |

22% |

Built in compliance with the main regulatory guidelines: