In the world of pharmaceutical and laboratory operations, cleaning isn’t just a routine task, it’s a critical factor in ensuring compliance, safety, and efficiency. Every component, from drums and hoses to glassware and plasticware, must be meticulously cleaned to prevent cross-contamination between production batches. But how do you ensure consistent, validated results across such a wide variety of equipment?

At IWT Pharma, we specialise in precision-engineered cleaning solutions that guarantee optimal exposure, maximum efficiency, and repeatable outcomes every single time.

Recap: What is a customised basket, and why is it so important?

In pharmaceutical and laboratory settings, contact parts such as valves, piping manifolds, and filters come in various shapes and sizes, making them difficult to clean and dry effectively using standard methods.

That’s where customised baskets come in.

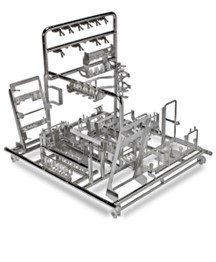

Each customised basket is bespoke, designed specifically for each customer’s unique components, to ensure optimal positioning for maximum washing and drying efficiency. These baskets are precision-engineered to interface seamlessly with the quick-lock connections inside the IWT parts washer chamber.

Here's how it works:

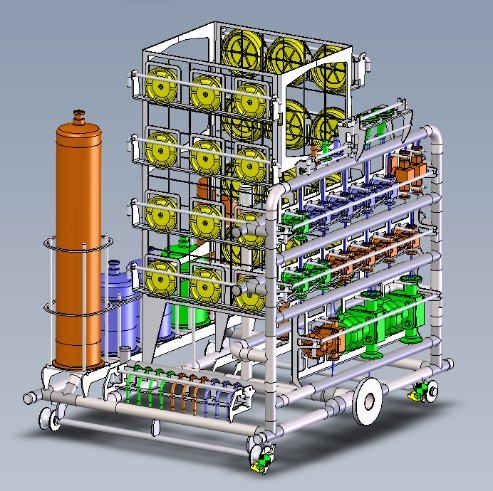

Below is our 200EVO, a contact parts washer together with a customised basket:

What Makes a Perfect Cleaning System?

Whether your cleaning needs are standard or highly specialized, five essential factors drive the effectiveness of our solutions:

Introducing the Flexi & Modular Basket System

For pharmaceutical facilities with standardised cleaning requirements, our Flexi & Modular baskets deliver unparalleled adaptability and efficiency. Engineered for precision and compliance, these customisable modules empower you to:

Tailored Cleaning Solutions for Specialised Applications

Not all pharmaceutical equipment is the same, so why settle for a one-size-fits-all cleaning solution?

For facilities dealing with custom or complex equipment, our tailored baskets provide a bespoke cleaning solution. Through:

Your Cleaning Process, Elevated

At IWT Pharma, our mission is to set the standard for pharmaceutical cleaning solutions. Whether you need a flexible, modular setup or a custom-engineered system, we are committed to delivering validated, repeatable, and fully compliant cleaning processes so you can focus on what matters most.